Mobilising knowledge assortment for accuracy within the cleanroom

The concept of mobilising knowledge assortment is vital to transferring cleanroom operation into Trade 4.0, and cell workstations is usually a large a part of that. Cam Shaheen from DTG explains

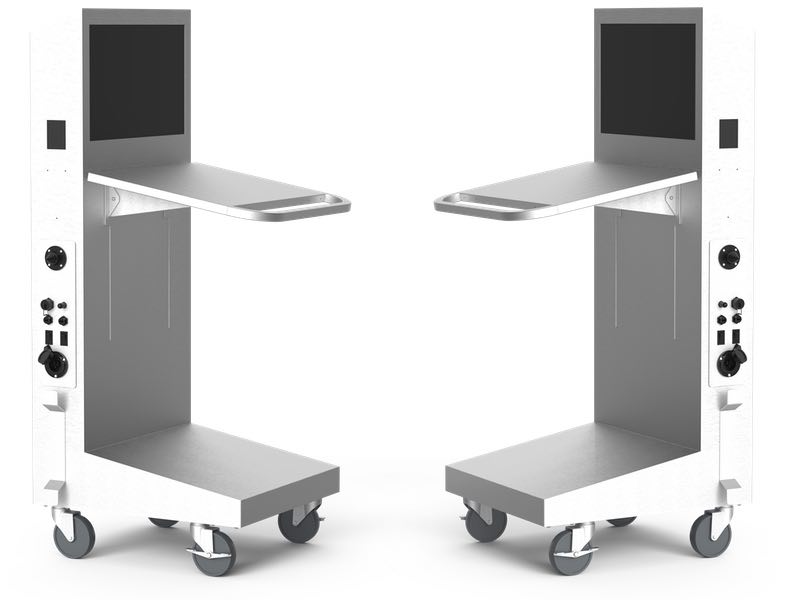

Cleanroom cart from DTG

For greater than 20 years, the FDA has clearly outlined its expectations for the accuracy, reliability and truthfulness of all knowledge and knowledge collected by drug producers. Most just lately it up to date its steering on guaranteeing knowledge integrity and compliance with present Good Manufacturing Apply (cGMP).

No matter altering rules, gathering and documenting sound and correct knowledge is essential to making sure the protected use of medicine or medical gadgets by shoppers.

But, from the analysis lab to the manufacturing plant, gathering and documenting high quality knowledge is less complicated stated than executed. When working in opposition to deadlines and making an attempt to effectively optimise costly GMP suite actual property, knowledge assortment is usually a time-consuming and typically error-prone course of that may trigger undertaking delays or initiatives that fail altogether.

As employees stroll throughout the lab to enter knowledge, they’re contributing to movement waste which not solely impacts timelines, but in addition knowledge integrity

For that reason, biopharma corporations are transferring away from guide knowledge assortment and paper-based manufacturing information since they want to have the ability to electronically seize and share knowledge.

To perform this, they’re utilizing Lab Info Administration Programs (LIMS) within the labs, to handle pattern monitoring, stock, system configurations, check outcomes, audit trails, high quality management (QC) knowledge, pattern/evaluation depend, instrument calibration and different knowledge that accounts for GMP necessities. Likewise, they’re utilizing Manufacturing Execution Programs (MES) within the suites, to watch, doc and management the method of producing items from uncooked supplies to completed merchandise and acquire correct digital batch information.

These methods enable them to retailer knowledge as digital recordsdata, in addition to determine points instantly, similar to inaccurate or duplicate knowledge or some other anomalies.

For workers who’re scientists first, electronically capturing knowledge is usually a robust transition

Automating knowledge assortment and documentation not solely reduces errors and permits knowledge integrity, it additionally boosts productiveness so corporations can get on with important analysis, discovery and manufacturing as a substitute of spending inordinate quantities of time getting into or reviewing knowledge. This sort of automation is the gateway to the next-generation in manufacturing, which is called Trade 4.0. In pharma manufacturing, Trade 4.0 will embody using interconnected, data-driven methods, sensors and ultimately autonomous methods.

Because of this, in response to McKinsey & Co., “within the subsequent 5 to 10 years, new applied sciences that characterise Trade 4.0—from connectivity to superior analytics, robotics, and automation—have the potential to revolutionise each component of pharmaceutical high quality management labs.” And, its analysis discovered that these applied sciences sometimes enhance productiveness between 50% to 100%.

Further productiveness busters

Whereas automating knowledge assortment and documentation processes would be the key driver to larger productiveness, it can also contribute to movement waste throughout the cleanroom. As employees stroll throughout the lab or plant flooring to enter knowledge right into a system residing on a set workstation, or to print out key paperwork, they’re contributing to movement waste which not solely impacts timelines, but in addition knowledge integrity, since knowledge will be misplaced on the way in which to the workstation.

Mobilising the information

One of many world’s largest pharmaceutical producers realised that the important thing to optimising the rising array of digital instruments required in pharma, similar to MES and LIMS, ERPs and undertaking administration methods, with out inflicting movement waste, is to mobilise them.

Earlier than this, the pharma agency first thought-about putting in fastened workstations throughout the positioning. But along with the price of the workstations, an even bigger price would come from having to utterly shut down cleanroom operations because the workstations have been being put in – this price would quantity to tens of millions of {dollars} in downtime. Not solely would this set up be disruptive, however the movement waste it will trigger, when workers needed to traverse the lab or plant flooring to enter knowledge, would considerably influence productiveness.

Because of this, the pharma agency selected to equip its workers with cell, battery-powered GMP workstations that housed a PC, monitor and scanner. They used these workstations to carry out knowledge assortment on their Digital Batch Data (EBR), allocate stock and monitor samples throughout a producing run. This eradicated any movement waste created by strolling to a set workstation and it decreased human errors by bringing knowledge assortment to the purpose of process.

Under are key issues for bringing computing energy to the biopharma lab or manufacturing plant.

Make digital instruments as straightforward as attainable to make use of

Particularly for employees who’re scientists first, electronically capturing knowledge is usually a robust transition. But, the simpler it’s to do, the extra receptive workers can be. It’s essential to take into accounts the inconvenience of transferring to a set workstation, or the frustrations of dropping laptop computer energy. It’s essential to hearken to and tackle consumer frustrations.

Present workers with every thing they want in a single place

One other approach to minimise movement waste within the cleanroom is to ensure workers getting into knowledge has every thing they want at their disposal, similar to PCs and scanners for executing MES or LIMs functions; in addition to distant battery chargers.

Take into account the ability supply

When several types of digital gadgets are mobilised within the cleanroom, a key concern is energy. It’s essential to have superior battery energy that may stand up to lengthy shifts, with 100% uptime. Employees will not be allowed to go away a cleanroom suite throughout a producing run and if a battery wanted recharging, they would want to cease the whole manufacturing run and scrap no matter merchandise have been made, amounting to lots of of 1000’s of {dollars} in misplaced batches or merchandise.

Digitalisation and the shift to Trade 4.0 is taking root in pharma, and enabling larger innovation and productiveness. It’s essential, nevertheless, to think about how these digital instruments are delivered within the cleanroom to not solely guarantee effectivity, however compliance to cleanroom well being and security necessities.