Spectrum Filaments has 8 new technical materials: Kevlar and Teflon Composites, as well as high-temperature, solvent-resistant engineering materials

By Spectrum Filaments

Spectrum Filaments – one of the largest European materials manufacturers for 3D printing in FDM / FFF technology, will present a range of 8 new technical materials at the Formnext 2022 fair in Frankfurt am Main. Composites of Kevlar (aramid fibres), PTFE(Teflon), carbon and glass fibers are some of them. The offer will also include high-temperature PPS AM230 material offering softening point (VICAT) as high as 236°C.

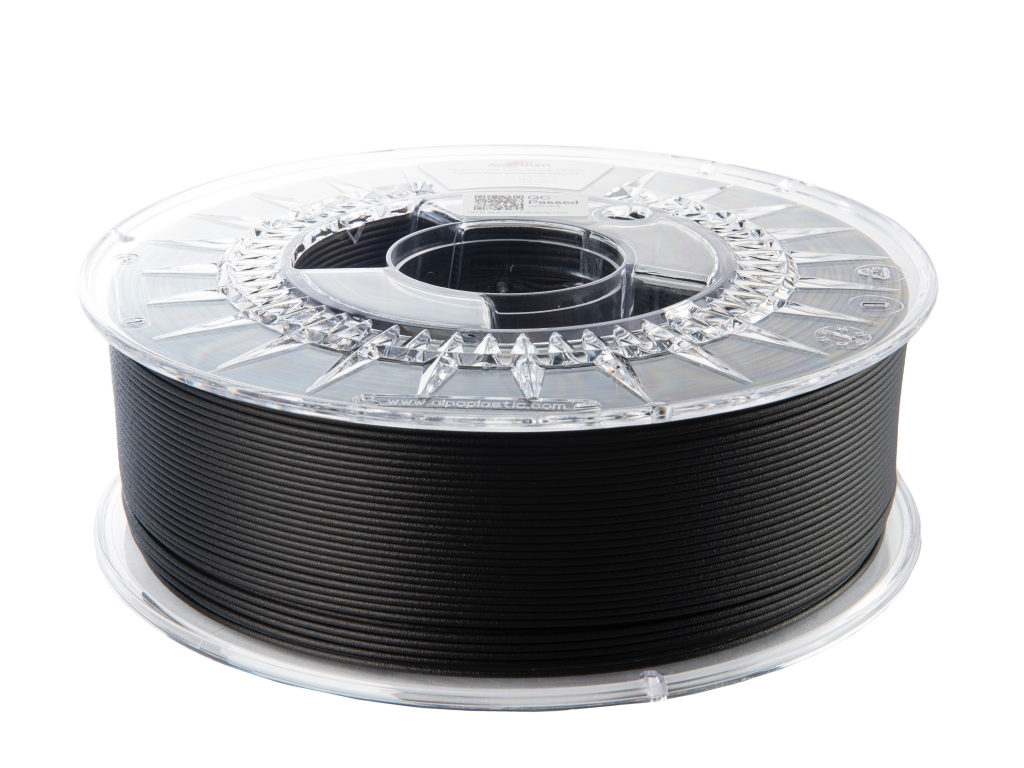

Spectrum Filaments is an additive manufacturing company that has been in operation since 2015. The company’s offer includes over 60 types of filaments in different variants, which translates into several hundred catalog products. The company sells and produces materials under its own brand. It also serves as a contract manufacturer for many reputable companies. The company’s filaments are dedicated to working with both amateur (budget) as well as desktop and industrial 3D printers.

Each manufactured spool undergoes a very precise quality control system – Verify your spool. During production, the filament is continuously measured in 2 axes with ±0.8µm accuracy, which creates a high-quality final product. Spectrum Filaments publishes individual parameters for each manufactured reel to prove it.

- The length of the spool in inches.

- mean diameter,

- ovality,

- standard deviation.

New Spectrum materials to be presented at Formnext 2022 will be available via the manufacturer’s distribution network in mid-November 2022:

ASA Kevlar

Spectrum ASA Kevlar is a technical composite filament based on the combination of ASA copolymer with aramid fibers – one of the strongest synthetic fibers. Aramid fibers can be used to make bulletproof vests and helmets as well as speaker membranes.

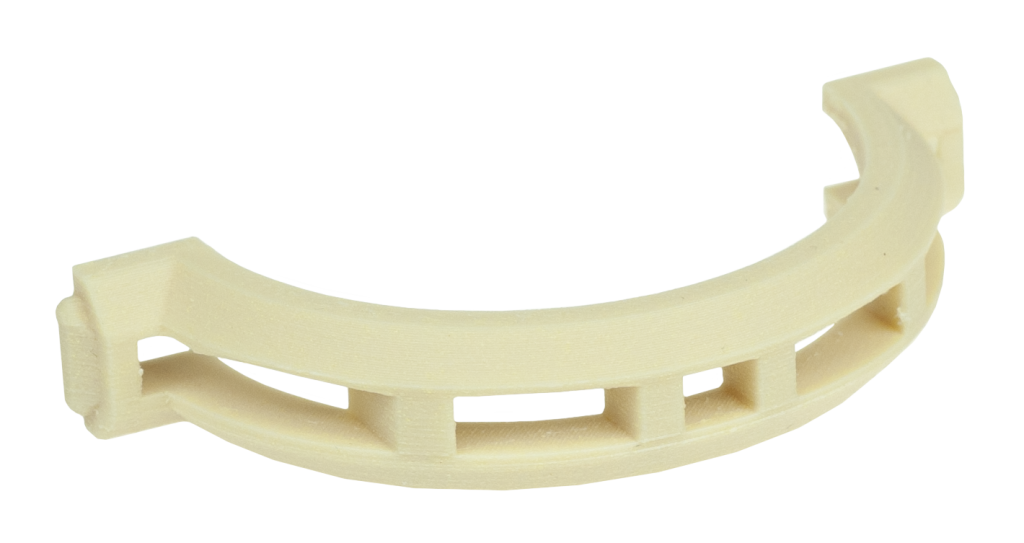

Aramid itself is a material that is poorly resistant to UV radiation, but as a result of combining it with ASA – a material highly resistant to this factor guarantees the long life of the fibers and the entire composite. Kevlar fibers are much less prone to abrasion than carbon and glass fibers. The use fibrous structures helps reduce material shrinkage during 3D printing, which allows for the production of large parts.

3D printing specs:

- printhead temperature: 240-270°C

- printbed temperature: 80-100°C

- Speed of 3D printing: 30-70 mm/s

- Heating chamber not required

ASA-X CF10

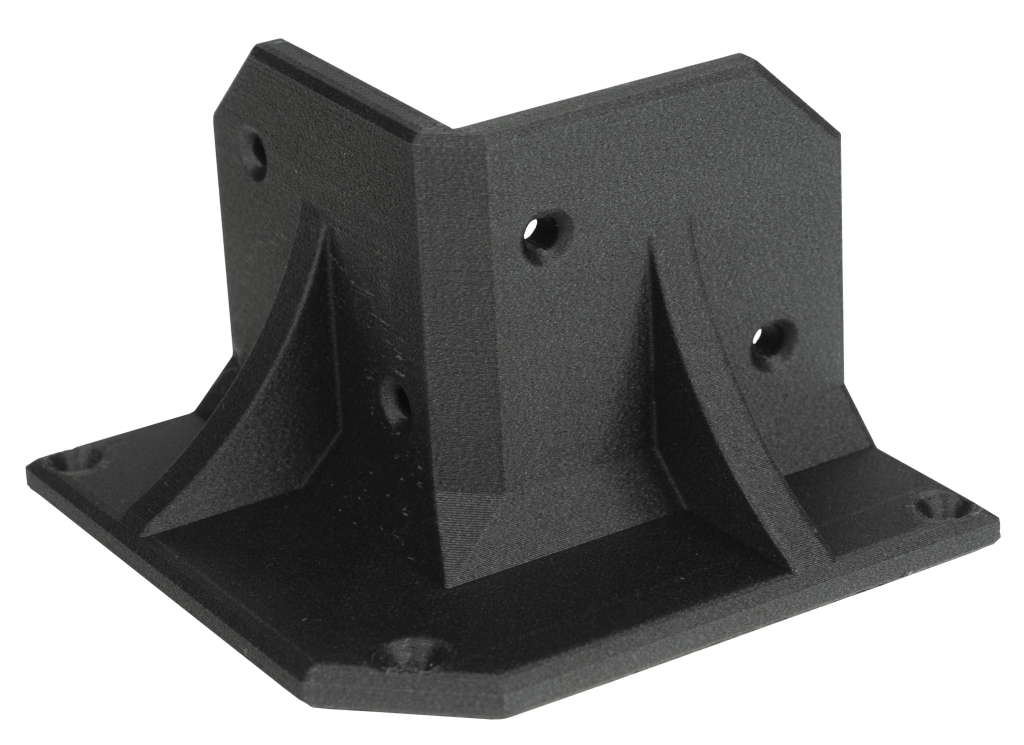

Spectrum ASAX CF10 material is highly resistant to external conditions and has a beautiful carbon finish. This filament is a ASA-based, composite filled with 10% carbon fibres. The material’s parts are resistant to UV and humidity. Its tensile modulus is over 7.5 GPa and its thermal resistance is 101°C. The Spectrum ASA-X CF10 has low shrinkage and easy printing.

3D printing specs:

- printhead temperature: 235-260°C

- printbed temperature: 90-110°C

- Speed of 3D printing: 30-70 mm/s

- Not required: Heated work chamber

PPS AM230

Spectrum PPS AM230 – a high-performance filament based on an engineering PPS polymer with exceptionally high mechanical parameters. Even under constant stress at high temperatures (above 100°C), the stiffness and strength remain unchanged. Spectrum PPS AM230 shows a softening point (VICAT) up to 236°C.

The filament is also characterized by remarkable chemical resistance – it is practically insoluble in any known solvent, including concentrated acids and bases. Spectrum PPS Am230’s natural nonflammability is a characteristic, even without the use of flame retardant chemicals.

3D printing specs:

- printhead temperature: 300-330°C

- printbed temperature: 100-120°C

- Speed of 3D printing: 30-70 mm/s

- heated working chamber: actively heated chamber (60-80°C)

PETG/PTFE

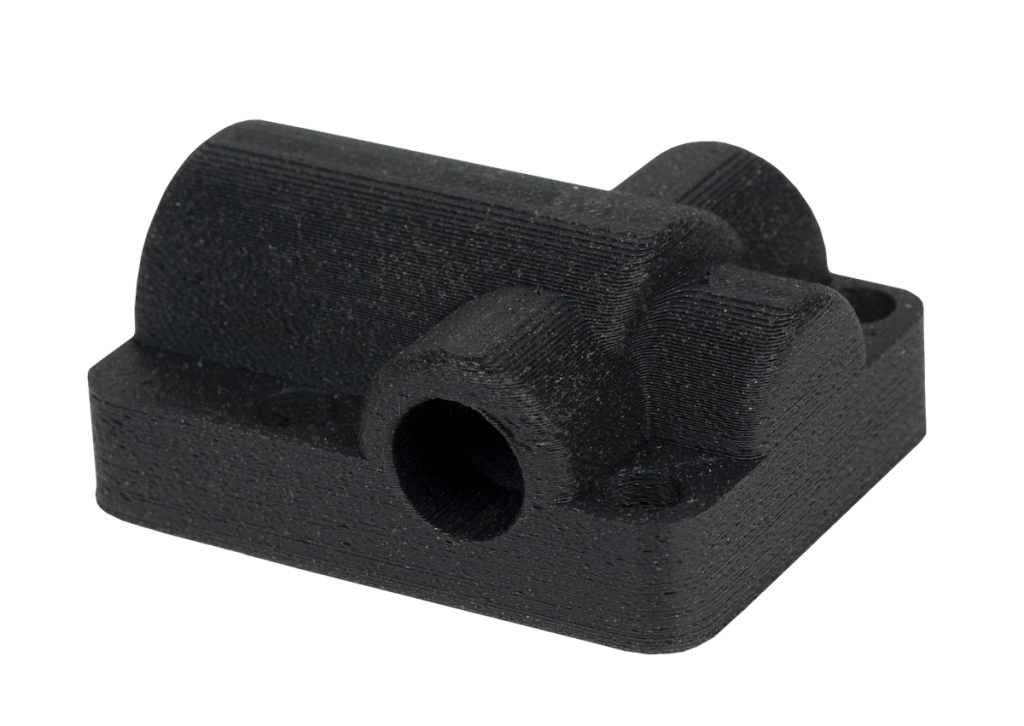

Spectrum PETG / PTFE – as a basis for the material was used Spectrum PET-G Premium, well-known for its excellent mechanical properties, is supplemented by adding 10% PTFE, commonly known as Teflon, with self-lubricating properties. The filament retains the PET-G’s excellent 3D printing capabilities, interlayer adhesion and thermal properties. The filament is available with different colors.

3D printing specs:

- printhead temperature: 235-255°C

- printbed temperature: 60-80°C

- Speed of 3D printing: 30-70mm/s

- Not required: Heated work chamber

PA6 Low Warp CF15S

Spectrum PA6 Low-Warp CF15S is a high performance part production line. The “LowWarp” line is characterized by additional admixtures aimed at improving the flow during 3D printing and better adhesion of material particles. 15% of carbon fibers results is more than a twofold increase in stiffness, and increased tensile strengths (up to 120MPa). In addition, Spectrum PA6 Low Warp CF15S has an improved HDT thermal resistance: 180°C (0.45MPa), compared to the unfilled version. The fiber content lowers the shrinkage characteristic for most high-temperature materials, significantly facilitating the printing process and gives the printouts an aesthetic, “carbon” look.

3D printing specs:

- printhead temperature: 250-280°C

- printbed temperature: <80°C

- Speed of 3D printing: 30-70 mm/s

- Heating work chamber: Recommended

PA6 Low Warp GGF30

Spectrum PA6 GF30 – a thermally stabilized 30% glass fiber reinforced copolyimide, mechanically improved in terms of tensile and compressive strength. The fibers are less aggressive, which reduces the risk of the 3D printer’s nozzle being damaged. This material is ideal for 3D printing parts that require high mechanical parameters, hardness, and thermal resistance. Spectrum PA6 GF30 has a temperature resistance of 180°C (0.45MPa), which puts it at the forefront of materials dedicated to desktop 3D printers.

3D printing specs:

- printhead temperature: 250-280°C

- printbed temperature: <80°C

- 3D printing speed: 30-70 mm / s

- Recommended: Heated working chamber

PCTG CF10

PCTG – a copolyester characterized by much greater impact strength compared to the popular PETG. The combination of high flexibility, layer bondability and low shrinkage make PCTG a great polymer to use in the composition of composite materials. Spectrum PCTG CF10 is a composite with carbon fiber – the fibers used give the filament extremely high stiffness, while reducing the brittle cracking characteristic of other copolyester-based carbon composites. They also increase thermal resistance, reduce shrinkage and give the characteristic “carbon” matte appearance to 3D printed parts.

3D printing specs:

- printhead temperature: 250-270°C

- printbed temperature: 50°C

- Speed of 3D printing: 30-80 mm/s

- Heating chamber not required

PCTG GF10

Spectrum PCTG GF10 composite is another one, but this time it is filled with glass fibers. It is extremely durable and has a matte finish. Similar to PA6 Low-Warp GF30 it uses fibers of a less aggressive geometry. This helps reduce the degradability of the 3D printer. Spectrum PCTG GF10 technical filament is high in stiffness and hardness. It allows for large prints even by intermediate users thanks to its high interlayer adhesion.

3D printing specs:

- printhead temperature: 250-270°C

- printbed temperature:> 50°C

- Speed of 3D printing: 30-80 mm/s

- Heating chamber not required