Mechanical efficiency and thermal stability of hardened Portland cement-recycled sludge pastes containing MnFe2O4 nanoparticles

Mechanical traits

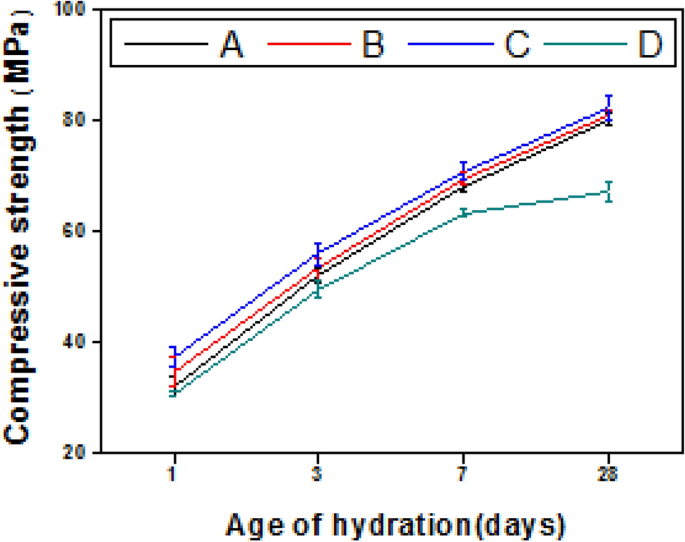

The mechanical efficiency of the hardened pastes or concrete might be specified by performing the compressive energy check. The findings of this check might be concise as follows: (1) as a basic pattern all examined samples confirmed steady energy rise with hydration progress (until 28 days), Fig. 6, this improve is ascribed to the progressive of the hydration response which induces the manufacturing of the various product that represents as an ideal binding middle by means of the hardened matrix, the fashioned phases are: calcium silicate hydrates (C-S-Hs), calcium sulfoaluminate hydrates (AFm and AFt), (calcium aluminosilicate hydrates C-A-S-Hs as gehlenite and hydogarnet) and calcium aluminate hydrates (CAHs), these outcomes might be helps by XRD, TGA/DTG, and SEM checks. (2) Upon changing OPC with 5% or 10% RAS, by mass (mixes B and C; respectively) a slight enchancment within the compressive energy values was recorded in comparison with paste produced from combine A (management) alongside all testing ages. Whereas a slight decline within the energy magnitudes was recorded when the substitute proportion of OPC with RAS reached 15%, Fig. 6. The notable enchancment within the values of compressive energy within the case of changing Portland cement with 5% or 10% RAS, by mass, may very well be correlated to the creation of additional hydrated yields; fashioned from the interplay between amorphous silica and alumina of sludge and lime generated from clinker hydration (pozzolanic response) forming an extra of CSHs, CAHs beside the creation of latest phases particularly as; MnCSH, CFH and CFSH50,51. Changing portlandite which possesses weak hydraulic character with CSHs, CAHs which possess good hydraulic traits causes the famous energy enchancment. In addition to, these supplementary hydrates perform as fillers for the present pores within the hardened matrix and act as an ideal binding middle between the remaining current unhydrated grains37. The notable noticed downward within the values of energy of combine D (85% OPC–15% RAS) is principally ascribed to the decline of clinker mineralogical phases throughout the composite which causes discount of each the primary merchandise (CSHs and CAHs) produced from its hydration, moreover discount the produced amount of portlandite that obligatory for the pozzolanic response49. From the recorded energy values the optimum substitute of OPC by RAS is 10%, the identical worth was reported beforehand52.

Compressive energy versus age of hydration for hardened blended cement pastes (mixes A–D).

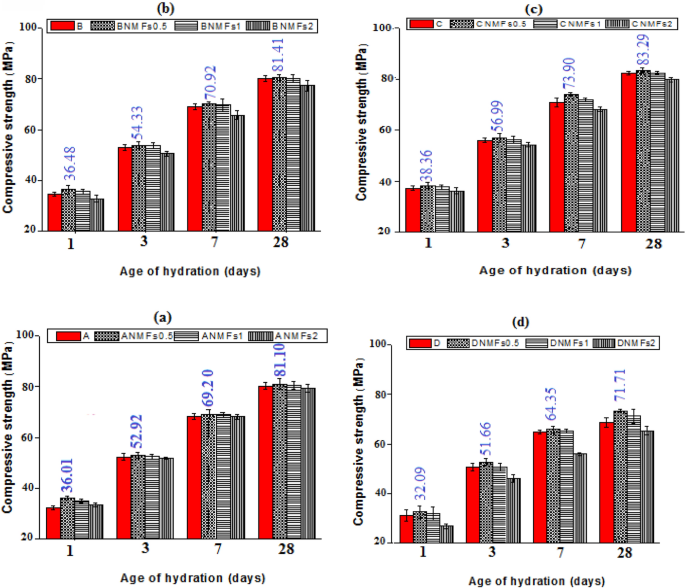

The affect of NMFs addition on the energy values of various composites was recognized and clarified in Fig. 7a–d. Clearly, the inclusion of 0.5 and 1% NMFs in numerous pastes (mixes ANMFs0.5, ANMFs1, BNMFs0.5, BNMFs1, CNMFs0.5, CNMFs1, DNMFs0.5, and DNMFs1) induces a slight enchancment within the energy values throughout all testing durations, whereas the inclusion of two% NMFs induced slight decline within the values of compressive energy, Fig. 7a–d. Though the right nanoparticles dimension of the ready NMFs (~ 13–40 nm), induced surprising slight modification within the values of compressive energy, these outcomes may very well be correlated to 2 components; (1) the cubic geometric construction of NMFs particles (see Fig. 2) which hindered their pore filling and current weak factors of contact between completely different phases current as reported in a earlier research45. (2) it could be correlated to the poor dispersion of the nanoparticles particularly when makes use of at excessive ratios37,40,53.

Compressive energy values of various hardened nanocomposites.

The slight decline in occurred within the values of compressive energy throughout nearly all hydration intervals for ANMFs2, BNMFs2, CNMFs2, and DNMFs2 mixes (2% NMFs addition) in comparison with their references (mixes A–D) could also be returned to the magnetic nature of NMFs particles. Manganese ferrite spinel is ferromagnetic in nature and its nanoparticles are interacting magneto statically, subsequently, they appeal to one another which induced their dangerous dispersion and promoted their coalescence46.

In conclusion, the findings assured that 90% OPC–10% RAS–0.5% NMFs composite (combine CNMFs0.5) may very well be reported because the optimum alternative for basic building purposes because it displayed the very best mechanical conduct amongst all examined nano-blends. These outcomes might be supported by additional carried out checks.

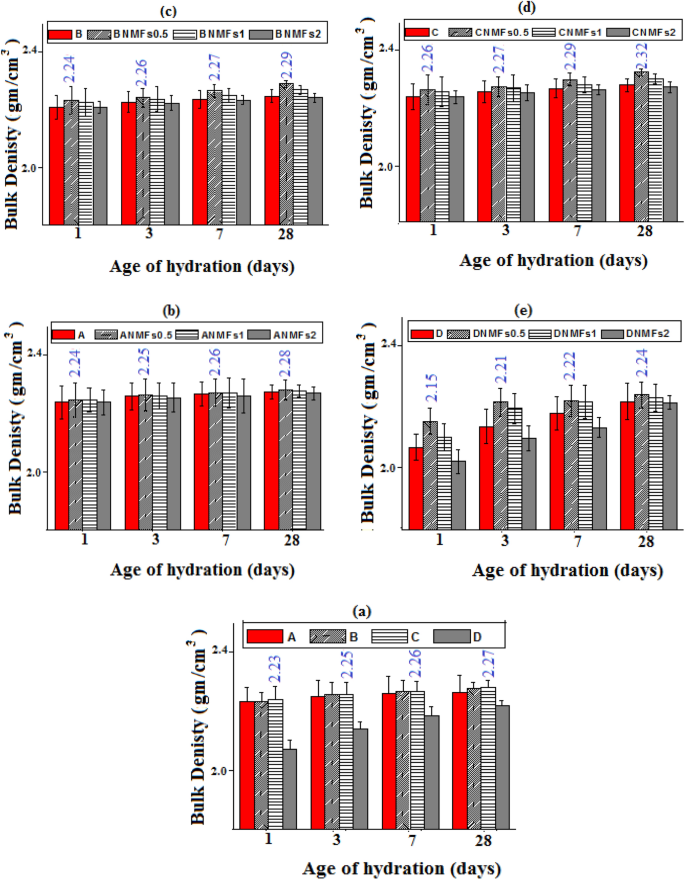

Bulk density (BD)

The densification progress of various composites with the progress of the hydration course of was adopted by measuring the BD values (g cm−3). The BD values for various blends indicated a steady gradual rising with hydration ages, Fig. 8a–e. These findings are assigned to the progress of the hydration course of and the buildup of various hydrated phases throughout the out there pores alongside the hardened matrix, producing compact and dense constructions48. Determine 8a signifies that specimens produced from mixes B and D (utilizing 5% or 10% RAS, by mass) introduced a notably larger BD worth (in any respect curing instances) relative to a clean (combine A). This discovering is correlated to the formation and accumulation of numerous forms of hydrated phases that fashioned by way of the pozzolanic interplay between out there liberated calcium hydroxide and RAS, making a denser matrix with excessive energy4. On opposite, the BD values when utilizing 15% RAS (combine D) are decrease and/or similar to a clean. These findings are in line with the beforehand talked about compressive energy information and ascribed to the formation of decrease portions of various hydration merchandise owing to the dilution impact of OPC phases by 15%34.

Bulk density values of various hardened composites.

The inclusions of various doses of NMFs (30.73 m2 g−1 and ~ 16 nm) as much as 1% enhance the BD of all composites throughout nearly all intervals of hydration, Fig. 8b–e. This enhancement may very well be correlated to the nano-filling impact and the acceleration impact of NMFs particles for the hydration course of by way of performing as energetic websites. The online results of the inclusion NMFs events is the era of extra portions of yields like CSHs, CASH, CAHs, CFH, CFSH, and MnCSH that accrued contained in the out there pores throughout the hardened composite matrix giving a extra compact and dense construction34,45,51. In addition to, the inclusion of two% of NMFs induces a slight decline within the BD values, because of the agglomeration impact of NMFs particle as talked about beforehand4. All these outcomes agreed with the compressive energy check outcomes and can obtain additional assist by way of the XRD, TGA/DTG, and SEM methods. The BD outcomes revealed that blend CNMFs 0.5 introduced the very best BD values matched to these of different mixes. This end result agreed and confirmed the obtained compressive energy outcomes.

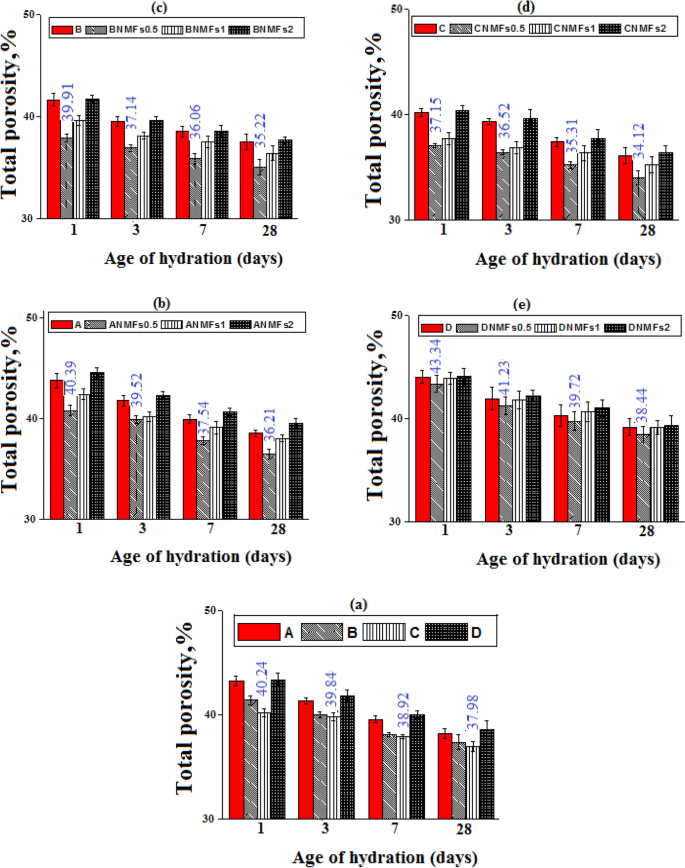

Complete porosity

Determine 9a shows the proportion values of whole porosity (TP%) of various composites after completely different testing durations. As a basic pattern, the TP% decreases for examined composites confirmed steady discount hydration until 28 days of curing. Usually, specimens of combine B and blend C indicated decrease TP (%), whereas combine D specimens confirmed comparatively larger values relative to combine A. Furthermore, the insertion of 0.5 and 1% of NMFs induced decrease TP% for the hardened nanocomposites, Fig. 9b–e. The addition of two% of NMFs to completely different blends offers hardened pastes with comparable and/or larger relative TP% values, in comparison with their controls (mixes A–D). Because the BD values improve, the TP% lower, and the compressive energy values improve48. Clearly, the obtained TP% values are agreed with the obtained outcomes of the energy and BD check and are ascribed to the identical causes talked about beforehand. Determine 9c shows that, CNMFs0.5 composites current the bottom TP%. Additionally, these outcomes will obtain additional assist from XRD, TGA/DTG, and SEM evaluation.

Complete porosity values of various hardened composites.

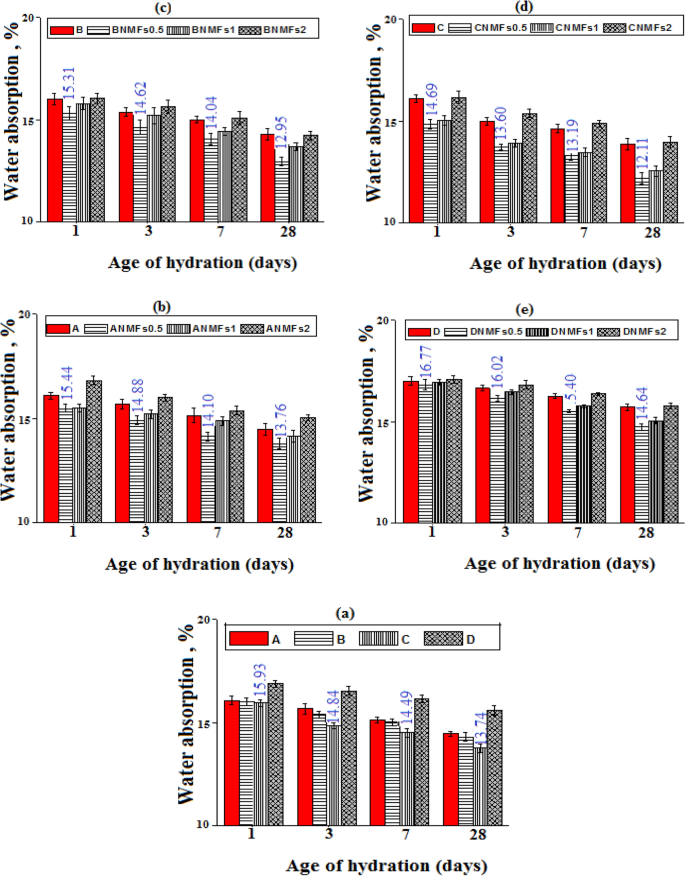

Water absorption (WA %)

The diploma of porosity of the hardened specimens might be recognized by way of the dedication of the WA%2. The share values of WA% for numerous examined mixes have been measured and displayed in Fig. 10a–e. As demonstrated from the obtained WA% values, indicated the identical pattern as TP% values for all examined mixes. Clearly, because the B.D values improve the TP% and the WA% decreases4. Clearly, all of the obtained outcomes for pore construction evaluation (BD.TP, and WA) are correlated with one another and agreed with the compressive energy check outcomes.

Water absorption values of various hardened cement composites.

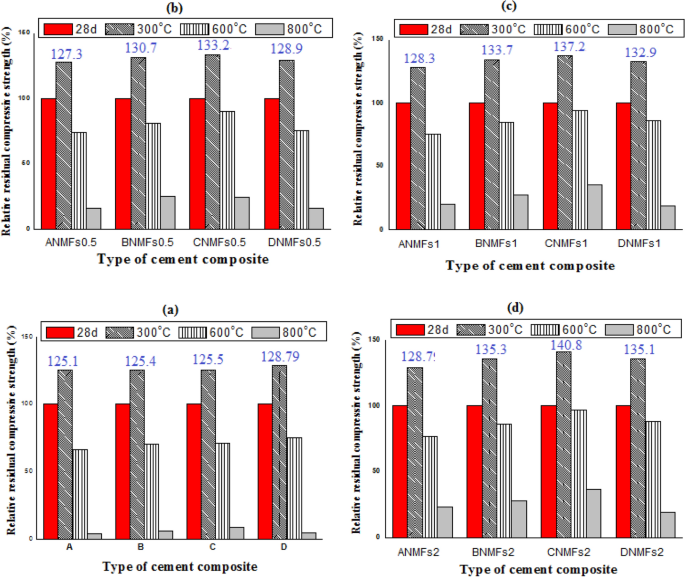

Stability towards firing (SAF)

The soundness of various hardened blends towards firing at 300, 600, and 800 °C for 3 h and cooled slowly within the air was recognized and represented as the proportion of residual compressive energy (RS%) in Fig. 11a–d. The findings of this check are: (1) all composites indicated a pointy improve within the RS (%) energy values when heating at 300 °C and cooled in air, in comparison with their recorded values at 28 days hydration, after {that a} important diminishing in residual energy upon firing at 600 or 800 °C was recorded, (2) inclusion of various quantities of NMFS in neat cement and/or blends boosts the SAF at completely different temperatures. The sharp boosting in residual energy (%) values for step by step cooled samples after firing at 300 °C is ascribed to the self-autoclaving (hydrothermal response) generated between the evaporation of bodily adsorbed H2O and remaining unreacted clinker phases, this inner autoclaving generates additional hydration product that fills the out there pores in addition to current extra binding facilities between completely different constituents current within the hardened composites2,48. The noticed diminish of RS (%) energy in step by step cooled specimens after being heated at 600 or 800 °C is correlated to the deterioration of most hydration merchandise (CSHI, CSHII, CASHs, CAHs, CFSH, CFH, MnCSH, and CH) and formation of microcracks alongside the matrix which has a powerful unfavourable affect on composites energy54. All nanocomposite pastes (incorporating numerous doses of NMFs) displayed larger resistance for firing (excessive RS%) in any respect utilized temperatures and cooling within the air relative to their controls after 28 days of hardening, additionally the SAF for these nanocomposites will increase with NMFs p.c. The optimistic affect of NMFs on the SAF of various composites is correlated to its filling impact on the current pores, its acceleration impact on the interior autoclaving response by performing as a nucleating middle for product formation45, and the magnetic nature of ferromagnetic spinel nanoparticles that results in magnetostatic interactions between the particles, selling the manufacturing of harden matrix possess excessive resistance to fireside deterioration46.

Relative residual compressive energy values for various fired cement composites after gradual cooling in air.

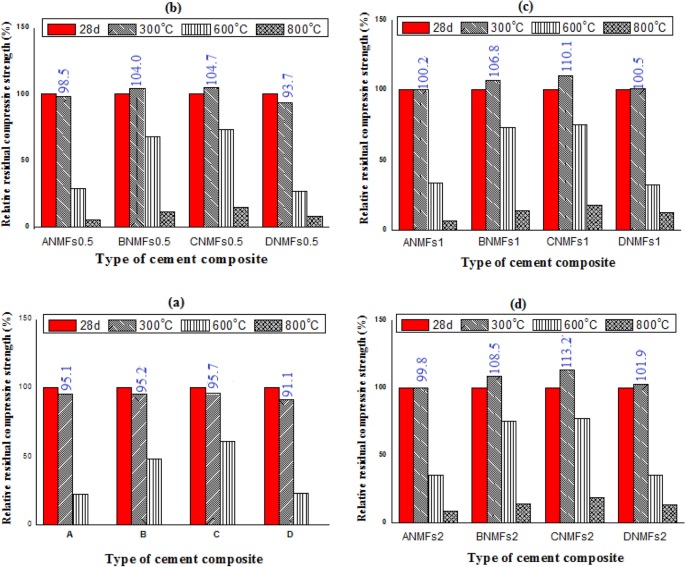

Determine 12a–d. show the RS (%) values for various composites after fast cooling (cooling in water) after firing at 300, 600, and 800 °C for 180 min. All composites endure a steady loss in energy upon being cooled in water after heating at completely different reported temperatures (300–800 °C), and the diploma of loss in energy will increase with temperature, Fig. 12a–d. Clearly, the diploma of depletion in energy is larger (RS% decrease) for all composites as in comparison with their loss when present process gradual cooling after therapy on the similar temperature. The intensive discount in compressive energy for the quickly cooled samples values is ascribed to the thermal shock to happen by the sudden cooling of fired specimens that causes the creation of a number of cracks in addition to enlarges of the microcracks current alongside the composite matrix34. As beforehand talked about in lots of research utilizing nanofiber/tubes as nano montmorillonite (NM) and carbon nanotubes (CNTs), Titania nanoparticles (TN)53,54,55 could delay the microcrack propagation by boosting tensile and flexural energy and bettering the microstructure homogeneity within the cement matrix53,56,57,58.

Relative residual compressive energy values for various fired cement composites after out of the blue cooled.

The share relative compressive energy (RCS) (relative to their CS after 28 days) for all fired specimens after gradual and fast cooling are clarified in Figs. 11 and 12, respectively. The RCS proportion values after firing at 300 °C and cooled slowly are 125.16, 125.4, 125.53, and 128.79 for (Mixes A–D).

The RCS percentages (relative to regulate at 300 °C and cooled slowly) for (Mixes ANMFs0.5-ANMFs2) are 127.37, 128.32, and 128.79%, respectively, 130.74, 133.78, and 135.39 for (Mixes BNMFs0.5-BNMFs2); respectively, 133.26, 137.23, and 140.87 for (Mixes CNMFs0.5-CNMFs2); respectively, and 128.90, 132.94, and 135.16, for (Mixes DNMFs0.5-DNMFs2); respectively, Fig. 11a–d. Visibly, the obtained SAF outcomes advocate the nanocomposite incorporates 90% OPC–10% RAS–2% NMFs to be the very best choice for thermal utility because it presents the very best % RS (highest SAF) at each gradual and sudden cooling in any respect reported temperatures, the recorded RS% values for this composite are 133.7, 137.2, and 140.8 for slowly cooled specimens fired at 300, 600, and 800 °C; respectively. Whereas the recorded RS % values for this composite are 104.7, 110.1, and 113.2 for quickly cooled specimens fired at 300, 600, and 800 °C; respectively. These findings nominated this composite to be the right choice for fireplace resistance utility.

Phases improvement

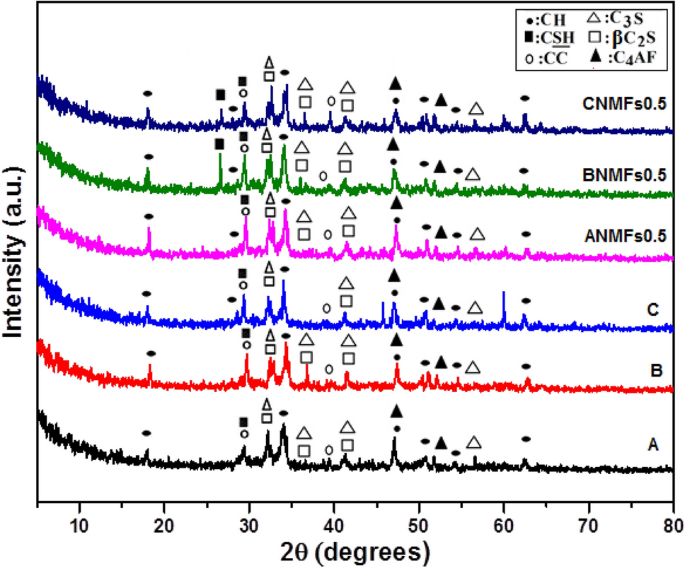

X-ray diffraction evaluation (XRD)

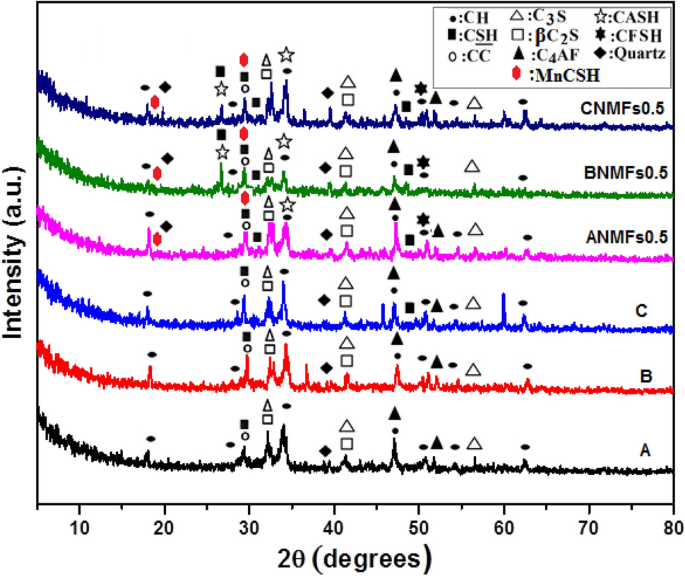

Figures 13 and 14 present the phases of improvement for composites composed of 100 OPC, 95 OPC-5 RAS, 90 OPC-10 RAS, OPC-0.5 NMFs, 95 OPC-5 RAS–0.5NMFs, and 90 OPC–10 RAS–0.5NMFs at 7 and 28 days hydration. The traits peaks of CSH and Ca (OH) phases have been recognized in XRD patterns for these mixes, moreover the peaks that traits to the unreacted quartz (crystalline silica), C3S (3CaO.SiO2), and β-C2S (2CaO. SiO2). Calcium carbonate was noticed at 2θ of ~ 29.32° fashioned from the response of lime (CH) with atmospheric CO2 fuel52. The XRD patterns of nanocomposites (composites admixed by 0.5 NMFs) revealed the looks of latest phases particularly at 28 days’ hydration particularly: ilvaite (CFSH) which is situated at 2θ 51°, MnCSH at 2θ 12.84, 18.36 and 29.6°, Nchwaningite [Mn2 SiO3(OH)2 H2O] (PDF#83-1006), Rancieite [(Mn, Ca) Mn4O9.3H2O] (PDF#058-0466), Glaucochroite [(Ca, Mn)2SiO4 (PDF# 14-376) located at 2θ 16.9°, and CFH51. These results support the obtained test results of compressive strength, BD, TP%, and WA% reported previously. The formation and later accumulation of these supplementary products promoted the development of densify microstructure possessing good mechanical characteristics and durability.

XRD patterns of hardened composites made from mixes (a–c), and nanocomposites made from mixes (ANMFs0.5–CNMFs0.5) at 7 days of hydration.

XRD patterns of hardened composites made from mixes (A–C), and nanocomposites made from mixes (ANMFs0.5–CNMFs0.5) at 28 days of hydration.

Differential thermogravimetric analysis

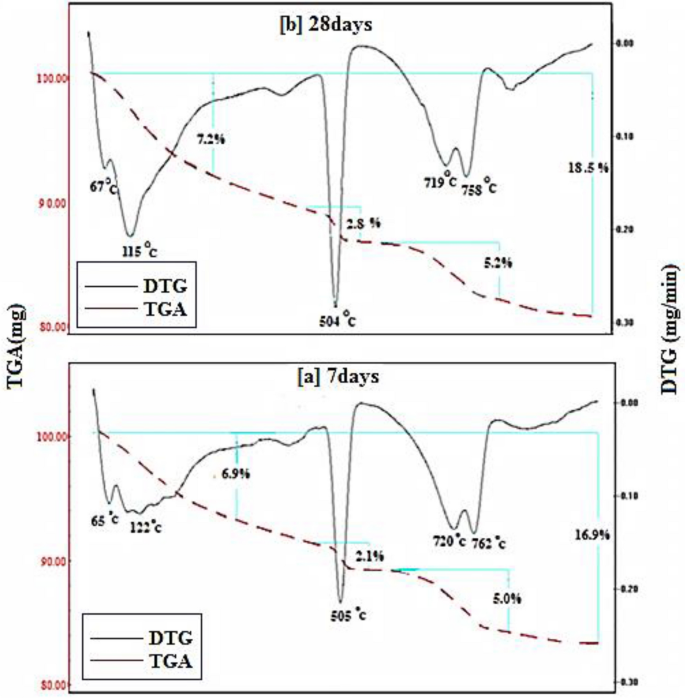

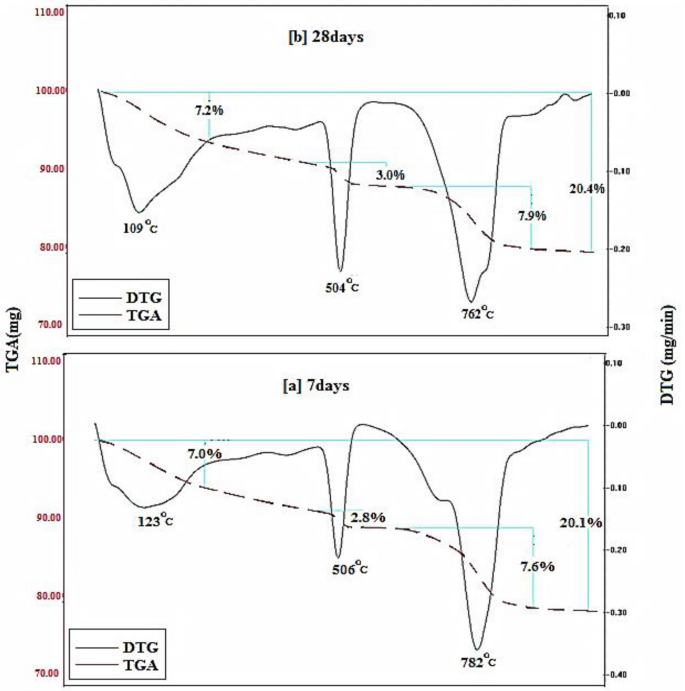

Figures 15, 16, 17, 18 demonstrates the TGA/DTA data for OPC, OPC-0.5NMFs, 90 OPC-10 RAS, and 90 OPC-10 RAS-0.5 NMFs (Mixes A, ANMFs 0.5, C, and CNMFs 0.5) at 7 and 28 days of hydration. The TGA/DTG results display three endothermic peaks located at ~ 70–180 °C, ~ 505 °C, and a double peak at 720 and 780 °C, for neat OPC samples at the selected times (7 and 28 days). The peak implanted at ~ 70–180 °C is devoted to the deportation of uncombined water and disintegration of the amorphous part of CSHs gel and calcium aluminate hydrates (CAHs), Fig. 15a,b4. The mass loss of this peak after 3 and 7 days of hydration is 6.9%, and 7.2%, respectively. The endotherm that appeared at 505 °C is correlated to the dehydration of CH (portlandite)4,59. The mass loss of this peak is 2.1% and 2.8% after 3 and 28 days of hydration, respectively. The observed increases in % mass losses in both endotherms are correlated to the formation of extra amounts of hydration phases (CSHs, ettringite, AFm, and CH) with the progress of the hydration process from 7 to 28 days2. The double peak present at 720 and 780 °C is ascribed to the degradation of calcium carbonates with different crystallinity, because of the carbonation of the specimens during its handling. The% mass loss values of these peaks are varied according to the degree of crystallinity and the degree of carbonation51,59.

TGA/DTG thermograms of hardened specimens made from mix A at (a) 7 days and (b) 28 days hydration.

TGA/DTG thermograms of hardened specimens made from mix ANMFs0.5 at (a) 7 days and (b) 28 days hydration.

TGA/DTG thermograms of hardened specimens made from mix C (a) 7 days and (b) 28 days hydration.

TGA/DTG thermograms of hardened specimens made from mix CNMFs0.5 at (a) 7 days and (b) 28 days hydration.

Figure 16a,b displays the TGA/DTG result of OPC-0.5 NMFs nanocomposite (mix ANMFs 0.5) at 7 and 28 days of hardening. The TGA/DTG behavior of this composite is identical to neat OPC (mix A) but with a higher % total mass loss value. The mass loss % of the diverse hydration yields is 16.9 to 18.5% (for OPC) and 19.2, and 19.8 (for OPC-0.5%NMFs) at 7 and 28 days; respectively. This finding ascertains the affirmative impact of NMFs on the acceleration of the hardening reaction of OPC and the simulation of the production of new phases (MnCSH, MnSH, and CFSH) as demonstrated from XRD data. This intern promoted the creation of hardened composite having good mechanical properties, higher BD, lower TP%, and lower WA values as previously mentioned in this study.

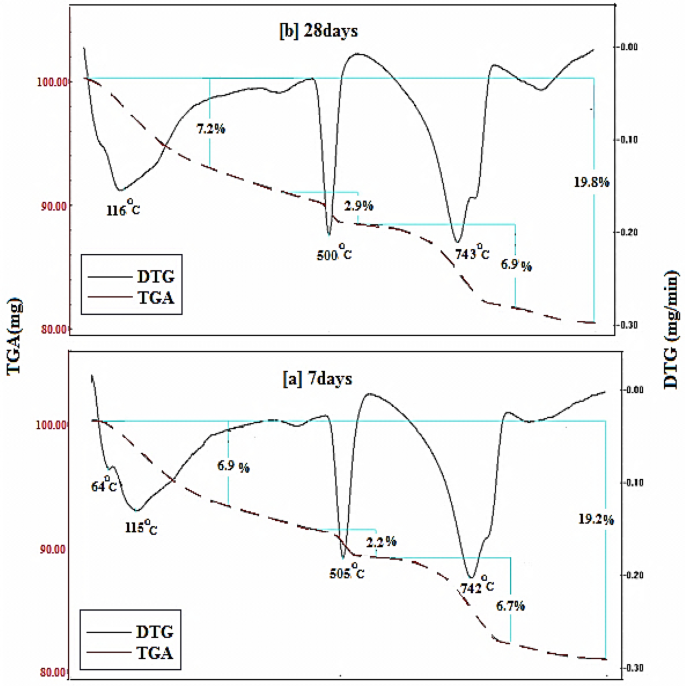

Figure 17a,b represents the TGA/DTG thermograms for hardened specimens that possess 90 OPC-10 RAS (mix C). Obviously, similar endotherms and behavior as blank are observed. The % mass loss of the peak present at ~ 70–180 °C is 7.0 and 7.1 while the peak present at 505 °C is 2.2 to 2.9 at 7 and 28 days; respectively. The variation in these values is ascribed to both the degree of crystallinity and quantity of the formed products. The detected peak at (~ 740 °C) is referred to as carbonates decomposition.

Obviously, the overall % mass losses for the formed hydrates are 18.2 and 19 at 7 and 28 days: respectively. The notable raising in the total mass loss relative to a blank (16.9 and 18.5) is related to the generation of extra amounts of nearly amorphous and crystalline CSH phase from the pozzolanic interaction between CH liberated from OPC hydration, and silica and alumina phases of RAS waste. These outcomes are compatible with the physical and mechanical test results reported mentioned previously.

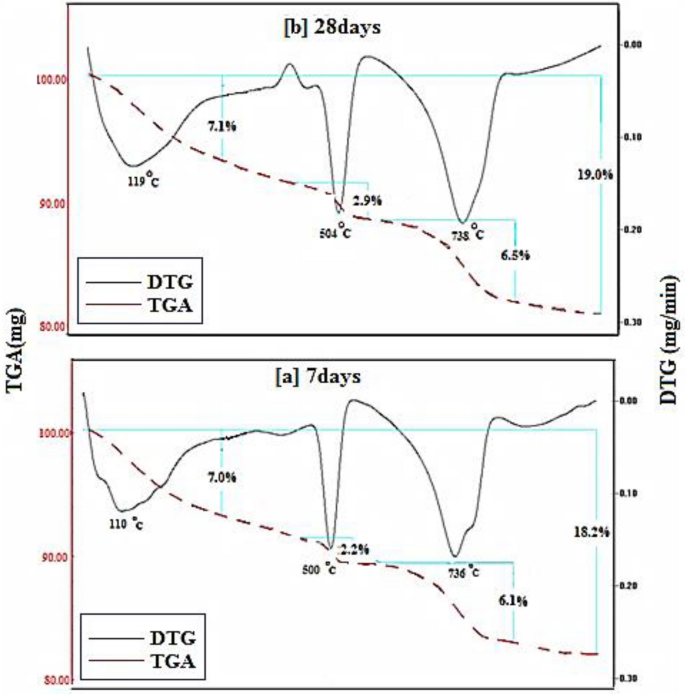

The TGA/DTA results for 90 OPC-10 RAS-0.5 NMFs nanocomposite (mix CNMFs0.5) after 7 and 28 days hardening are identified. The TGA/DTG findings of this mix demonstrated similar peaks and behavior as mix C, Fig. 18a,b. The overall mass reduction percentages are 20.1 and 20.4% at 7 and 28 days, respectively; these percentages are relatively higher than that of other mixes (A, ANMFs0.5, and C). The notable higher overall mass loss of these nanocomposites is credited to the reinforcing effect of NMFs particles as discussed previously. Also, the TGA/DTG results are corroborated with all previously mentioned results (RS, TP, BD, and WA).

Microstructure

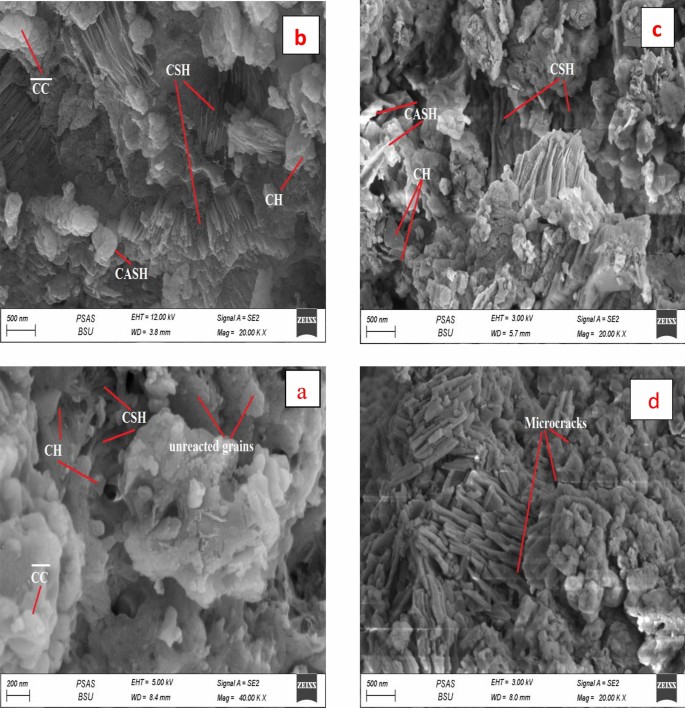

Figure 19a,b clarifies the morphological features for mix A specimen at 7 and 28 days hydration intervals. The SEM investigation of this mix affirms the appearance of a porous matrix diffused by some fibrous and ill crystals of CSH as a principal product from clinker hydration at 7 days. Also, small hexagonal plates of CH were detected along the matrix, little amount of CC̅ besides a large quantity of unreacted clinker grains could be well distinguished, Fig. 19a. The micrographs of this mix at 28 days’ hydration displayed a dense matrix composed of excessive quantities of microcrystalline and fibrous CSH, the large amount of CH also existed as stacked hexagonal crystals. Besides, little crystals of CC̅ are found in the matrix, Fig. 19b. The SEM micrographs also illustrated the existence of a few voids in the matrix accessible for the deposition of new hydration products.

SEM micrographs of hardened specimens made from mix A: (a) after 7 days, (b) after 28 days, (c) after firing at 300 °C and (d) after firing at 800 °C.

The effect of firing on the microstructure of neat OPC samples is investigated and given in Fig. 19c,d. Firing the hardened OPC sample at 300 °C and cooling it in the air (slow) induced the formation of a highly compact matrix composed of an excessive amount of nearly amorphous fibrous C–S–H (the major hydration products) interlocked by the hexagonal plates of CH. These microstructure features reflect the internal autoclaving reaction of unreacted OPC grains that causes the generation of an extra product (CSH, CH, CAHs, CASHs), promoting the formation of the dense structures having advanced properties (high strength, low porosity, high density). This finding confirmed the obtained data from RS, BD, WA, and TP tests. The microstructure of the OPC specimen exposed to a higher temperature (800 °C) and gradually cooled, revealed the formation of several micro-cracks, with the absence of any hydration products because of their decomposition. Certainly, the degradation of hydration products and the existence of microcracks are essential reasons for the deterioration of these specimens, Fig. 19d.

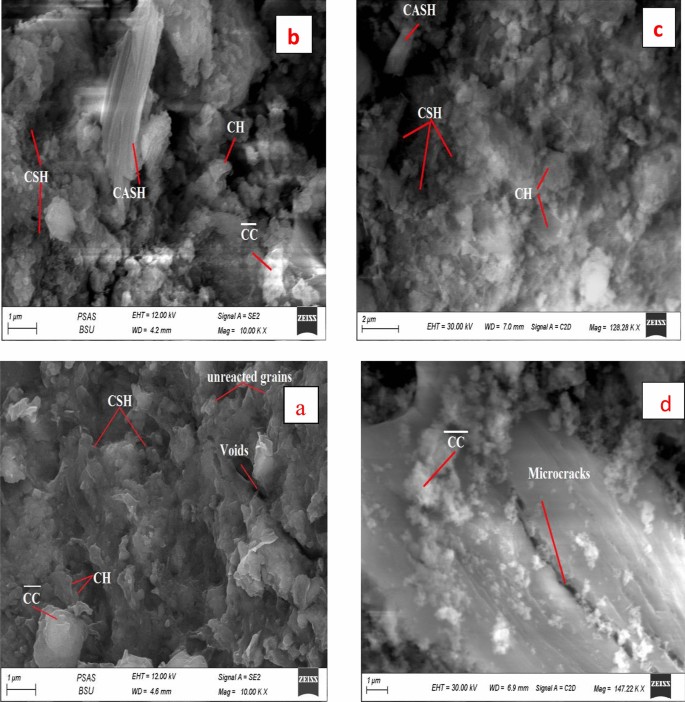

Figure 20a,b displays the microstructure of hardened specimens made from 90% OPC + 10% RAS + 0.5% NMFs (mix CNMFs0.5) at 7 and 28 days, respectively. The SEM micrographs of these nanocomposites indicated the following: (1) specimens hydrated for 7 days showed less dense microstructure has little amount of hydrated phases, and excess particles of unreacted clinker compared to the microstructure of specimens hydrated for 28 days, (2) Replacing cement with 10% RAS, induce the production of excess amounts of hydrated phases (CSH, CAHs, CASHs), this intern enhance the microstructure features and the densification characteristics of these nanocomposites compared to the neat OPC paste at the same curing ages, Fig. 20a,b and (3) the activation rule of NMFs particle was ascertained by the dense and nonporous matrix displayed by the SEM images of these nanocomposites (Fig. 20a,b). The NMFs particles induce the formation of enormous hydrated phases as its rule as active site and via its reaction and formation of a diverse product that appeared in the micrographs like; micro rods and fibrous crystals of CSHs, plates of CASHs, fine crystals of CFSH, CFH, MnCSH and fibers of AFt (3CaO·Al2O3·3CaSO4·32H2O); all these products are interlocked with each other and intermixed with little hexagonal crystals of CH, producing compact, non-porous structure having good mechanical properties60. The SEM study fastened the physico-mechanical results obtained in this study.

SEM micrographs hardened nanocomposite made from mix CNMFs0.5: (a) after 7 days, (b) after 28 days, (c) after firing at 300 °C and (d) after firing at 800 °C.

The effect of firing at 300 and 800 °C and cooling in the air on the microstructure of these composite is displayed in the SEM image, Fig. 20c,d. The specimens made from 90 OPC-10RAS-0.5NMFs indicated stable microstructure having good thermal resistance compared to control specimens (neat OPC) when exposed to the same conditions. The inclusion of NMFs particles in this composite promotes its resistance to thermal degradation as a result of its magnetic nature47. The microstructure upturn of this blend has also correlated with the presence of RAS as previously discussed.