Could a 3D-printed device be the answer to more powerful cell phones and WIFI?

All over the world, 3D printing has been used in a variety of amazing ways. There are many applications for additive manufacturing, including bioprinting and 3D printing in construction. Researchers from Harvard John A. Paulson School of Engineering and Applied Sciences have discovered yet another use for additive manufacturing. They have created a 3D printed device that could be used for braiding filaments smaller than 1 micrometer in diameter. This could open the door to antennae that can access higher frequencies for the next generation phones and wireless devices.

Although cell phones have been around since the mid-70s and WIFI since late 90s, the technology has undergone rapid advances due to the increasing globalization and demands of the online population. WIFI is becoming more powerful and faster. South Korea is the top country for WIFI connectivity with speeds up to 28.6Mbps. In the same way, cellphones have evolved rapidly over the past 20 years. They have gone from being bulky and cumbersome phones that could only handle a few tasks (such as calling) to tiny, portable computers that can be carried in our pockets. However, if we want to advance even further, we need to be creating new antennae to access new ranges, however today’s industrial fabrication techniques will not work on fibers that are small enough to make them according to the Harvard team as they cannot be braided together. Enter 3D printing.

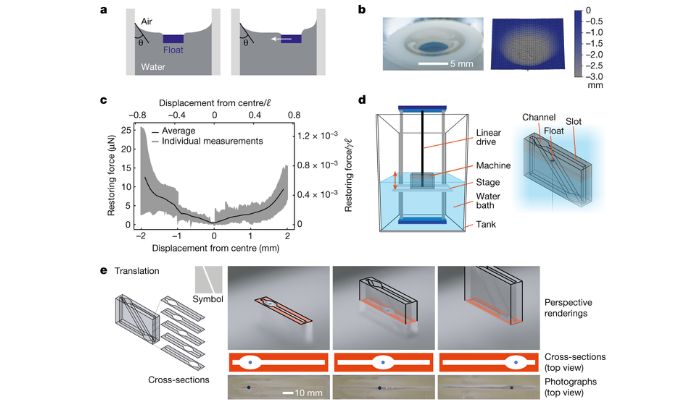

The team used 3D-printed devices to manipulate microscopic items through capillary forces, as shown in these diagrams (photo credit: SEAS).

What are the uses of 3D printing?

Engineers and scientists were astonished at the simplicity of the solution. They used water’s surface tension to grab and manipulate microscopic items. The team used a machine that was basically a 3D printed plastic rectangle about the same size as a Nintendo cartridge, and whose interior was carved out with intersecting channels. These channels are both broad and narrow, reminding of a river which expands in one part and narrows in another. The channel walls are hydrophilic, which means they attract water. The team mentions that the rectangle could also be made with a simple 3D printer found at a library. However they do not specify a brand.

The object works because it uses capillary forces. Capillary action, which is the process by which liquid flows into a narrow space and without assistance from forces like gravity, is crucial when it comes to moving water. Submerging the device into water and placing a plastic float of a few millimeters in the channel, created surface tension that caused the wall to repel it. It moved in a narrow section as far as it could from the walls, while in a larger section it would remain in place, trapped between the walls and the floating float. Researchers discovered that the fibers could be twisted around each other as water levels changed and floats moved.

Maya Faaborg (associate at SEAS) and co-author explained. “The eureka moment came when we found we could move the objects by changing the cross-section of our trapping channels. It was a shout-out-loud-in-joy moment when — on our first try — we crossed two fibers using only a piece of plastic, a water tank, and a stage that moves up and down.” The final step involved adding a third floating fiber to the float and creating channels to move it in braiding. This was used to braid micrometer-scale Kevlar fibres.

Although the research is still in its infancy, it has enormous implications for the future. The team plans on continuing to develop devices that can manipulate multiple fibers simultaneously to determine if they can make high-frequency conductors, which could then be used to create more powerful wireless devices (WIFI), and cell phones. This success is due to 3D printing’s accessibility and ability to create complex geometric structures. You can read the entire study HERE, or watch the video below to learn how it works.

What do these researchers think about how the 3D printed device was used by them? Let us know in a comment below or on our LinkedIn, Facebook, and Twitter pages! Don’t forget to sign up for our free weekly Newsletter here, the latest 3D printing news straight to your inbox! You can also find all our videos on our YouTube channel.

*Cover Photo Credits: SEAS